Lampwork Beads

Lampwork beads are a type of bead made from glass, and it's no surprise, because glass is an artisan's dream. It can be poured into molds. It can be cut and polished into faux gemstones. It can be stretched and pulled into any shape imaginable. It's no wonder that creative people throughout the world choose to express their artistic talents with glass.

How Lampwork Beads Are Made

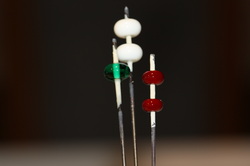

Mandrels coated with bead release are used to make lampwork beads.

To create glass beads, lampworkers melt narrow rods of glass with the flame of a torch. The molten glass is wound around a mandrel, a thin length of stainless steel. The space occupied by the mandrel becomes a hole through the bead when the bed is slipped away. Turning the mandrel and holding it in different positions allows gravity to help the bead take form, but tools are also used to push and pull glass beads into shape. Lampworking is a skill that takes a great deal of practice and patience. A lampwork bead artist understands the glass and the torch, and must learn how much heat it takes for glass to flow, how much heat can be applied to a bead that's already shaped before it becomes molten again and loses shape, when to add decorative elements and how different colors of glass interact with each other.

What Lampwork Beads Look Like

Hand crafted glass beads can be as plain or as decorative as the artist likes. Multiple layers of glass are often used, switching colors to create the desired look. Small dots of color can be left as bumps on the bead's surface or plunged into the center where they form floral-like designs. Fine lines are possible when craftspeople work with tiny rods of glass -- kind of like painting with a glass paintbrush.

How Lampwork Beads Are Stabilized

Glass shrinks as it cools. Bringing a bead out of the flame and leaving it in the open air allows the outside of the bead to cool rapidly, but its inside is still burning hot. The stress point between the cool, shrinking glass and the hot center begins to grow and often causes the bead to crack. To prevent stress and cracks, beads are cooled in a kiln, where temperatures can be closely regulated. The beadmaker "soaks" the beads at a high temperature to make sure that all glass within them is evenly heated, then takes several hours to slowly reduce the heat to bring beads to room temperature. The process is called kiln annealing. and it's important to make sure that the handcrafted glass beads you buy from craftspeople are kiln annealed. Tiny glass beads are sometimes cooled between layers of insulation. It's not the same as annealing, but the process is usually successful because it helps small amounts of glass cool at the same rate.

More Information on Lampworking

A Few Sticks of Glass